Lh Series High Precision High Speed Horizontal Machining for Casting Products

Brief Introduction of LK Group LK, as one of the global leader in machine tool manufacturing, LK engages in the design,

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | LH-500 |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Die Casting Machine Type | Cold Chamber Die Casting Machine |

| Die Casting Method | Precision Die Casting |

| Machining | CNC Machining |

| Material | Aluminum Alloy |

| Surface Preparation | Polishing |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 1 |

| Speed | High Speed and Stability |

| Function | for Machining Die Casting Parts |

| CNC Control System | Mitsubishi M80 |

| Transport Package | Wooden Packing |

| Specification | 510*420*350 |

| Trademark | LK |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 1000 Sets/ Year |

Product Description

Brief Introduction of LK GroupLK, as one of the global leader in machine tool manufacturing, LK engages in the design, manufacturer and sale of three product lines, i.e. die casting machines, pleastic injection modling machines and CNC machining centres. With the state of the art facilities and technology, LK builds high-performance solutions to meet industry needs in the past 40 years. LK was founded in 1979.

The LK product brand grows with our customers, with over 33,000 die casting machines which are ruuning the world, accounting of approximately 50% market share in China die cascting industry, and remarkable market share in India, Brazil, Australia, South African, Thailand, Indonesia, Malaysia , Japan, USA, etc.

To further expan out footprint, LK acquired one of the world's leading die casting machine manufactures IDRA IN 2008. Nowadays, there are 8 production bases in China .

Introduction for the CNC Mamchining Center

No matter of machinery / assembly parts, or general machining for molds, MV, MT, BTC series vertical machining centers can let you have the efficiency in production, which is definitely an economic investment.

- MV series can be used for machining general mechanical and assembly parts, die casting parts and mold processing.

- MV has spindle speed of 8,000 rpm, suit most general machining.

- MVP series has spindle speed at 10,000 rpm for precise machining for high requirement casting parts, components.

- MVD series has spindle speed at 12,000 rpm for die and mold components machining.

- MT-1400 has 3 axes roller linear guides for high rapid travel

- 5-axis high-speed bridge type machining center BTC series is available for most complex and high requirement products.

Factoy view

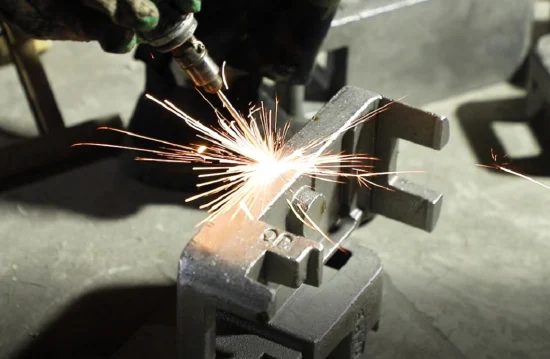

Here are a part of products produced by LK