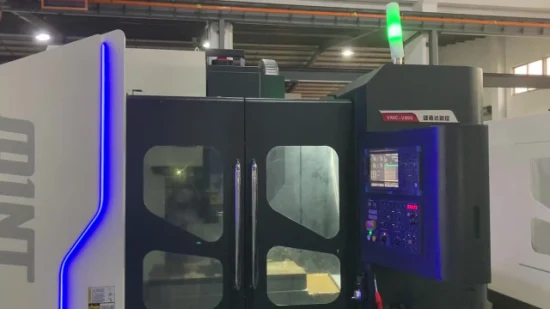

High Speed CNC Milling Machines Vertical Machining Center 3 Axis Machining V855

High Speed Cnc Milling Machines Vertical Machining Center 3 axis machining V855Fast speed and high efficiency create val

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | VMC-V855 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.006mm/M |

| Performance Classification | High-End CNC Machine Tools |

| Certification | ISO 9001 |

| Condition | New |

| Table Size | 1000*550mm |

| Machining | Mold and Parts Machining |

| Rotation Speed | 10000/12000/15000rpm |

| Spindle Taper | Bt40 |

| X Axis Travel | 800mm |

| Y Axis Travel | 550mm |

| Z Axis Travel | 550mm |

| Distance Between Spindle and Nose | 120~670mm |

| Spindle Power | 7.5kw |

| Spindle Type | Belt or Direct Spindle |

| Spindle | Short Nose Spindle |

| Three Axis Type | Linear Guide Way |

| Minimum Set Moving Unit | 0.001mm |

| Table Load | 600mm |

| T Slot | 5-18*100 |

| Transport Package | Wooden Package |

| Specification | 2650*2900*2750mm |

| Trademark | JOINT |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 30 Sets |

Product Description

High Speed Cnc Milling Machines Vertical Machining Center 3 axis machining V855Fast speed and high efficiency create value

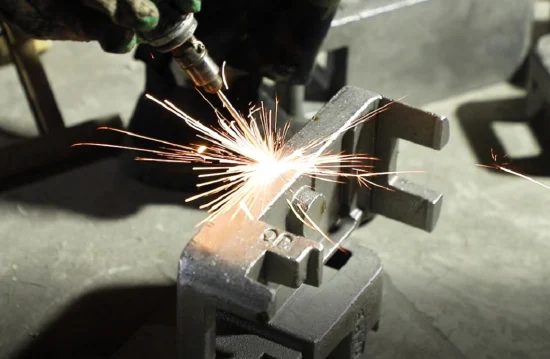

V series CNC machine center has the characteristics of fast feed speed and high rotation speed, so it is suitable for batch parts with many tools, complicated processing and multiple processes. Mainly processing cabinets, complex curved surfaces, heterosexual parts, disks, sleeves, plate parts, etc., are widely used in electronics, machinery and automotive, automation, medical, national defense and other fields.

Features

1. V-series machines are designed for high efficiency parts processing. Three axis adopt ball linear guide way or roller linear guide way , rapid feed:48m/min2. The unique large-span structure of the base and column can withstand the inertia caused by high G with high overall dynamic response.3. The direct-connected short nose high-speed spindle can improve efficiency, reduce tool wear and maximize the transmission efficiency of the spindle motor. Improving processing accuracy and extending spindle life.4. Equipped the rear chip conveyor with a large flow chip removal system, which can meet the requirements of rapid chip removal..

Specification

| Model | V855 | |||

| Travel | X axis travel | mm | 800 | |

| Y axis travel | mm | 550 | ||

| Z axis travel | mm | 550 | ||

| Distance between spindle and table | mm | 140-690 | ||

| Distance between spindle and column | mm | 590 | ||

| Table | Size | mm | 1000*550 | |

| Load | kg | 500 | ||

| T slot size | mm | 5-18*100 | ||

| Spindle | Taper | BT40-150 short spindle nose | ||

| Install diameter | mm | 150 | ||

| Rotation speed | r/min | belt 10000/ direct 12000/direct 15000 | ||

| Three axis | Cutting feed | m/min | 15 | |

| Rapid feed | m/min | 48/48/48 | ||

| Arm type Tool magazine | Tool capacity | T | 24 | |

| Maximum diameter/ length/ weight of tool | mm/mm/kg | 80/200/8 | ||

| Maximum diameter of tool (no tool) | mm | 150 | ||

| Tool change time (T-T) | s | 2.8 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.006/0.006/0.006 | |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.005/0.005/0.005 | ||

| Other | Dimension | mm | 2550*2850*2800 | |

| Power capacity | KVA | 15 | ||

| Weight | kg | 5300 | ||

Standard accessories:

1. Mitsubishi/ Fanuc controller system with AICC2 Function 2. Fully enclosed cover3. Pneumatic system4. Anto lubrication system5. Work piece coolant system6. Heat exchange7. Air gun8. Water gun9. Spindle oil coolant10. 24T Arm type tool magazine11. Rear flishing12. Hand wheel13. RS232 Interface14. Alarming light15. Working light16. Guide way cover17. Technical documents18. Operation manual

Optional accessories:

1. Screw type conveyor2. Chain type conveyor3. 4 axis Rotary table4. Coolant through spindle (CTS)5. 15000RPM/24000Rpm optional

Machine body finite element analysis Extra wide base High rigid roller linear way

No heavy balance weight design Column big-span Reinforced spindle boc

Application Industry

Car front floor stiffener Mechanical parts

Hardware parts Automobile wheel hub machining

Related Products

-

![for Polaris Plr Rzr XP/ Rzr 4 S General 1000 2014-2019 UTV Parts 1322743 Metal Primary Drive Engine Start Clutch Master Kupplung]()

for Polaris Plr Rzr XP/ Rzr 4 S General 1000 2014-2019 UTV Parts 1322743 Metal Primary Drive Engine Start Clutch Master Kupplung

-

![OEM Customized High Speed Aluminum Plate Parts Auto Parts CNC Machining]()

OEM Customized High Speed Aluminum Plate Parts Auto Parts CNC Machining

-

![Cowtotal China Wholesale Price Auto Spare Parts for Japanese Car Toyota Nissan Mazda Mitsubishi Honda Infiniti Suzuki Camry Cr-V Hilux Yaris Avensis]()

Cowtotal China Wholesale Price Auto Spare Parts for Japanese Car Toyota Nissan Mazda Mitsubishi Honda Infiniti Suzuki Camry Cr-V Hilux Yaris Avensis

-

![Seibu EDM Consumable Parts Water Nozzle Lower 4465971]()

Seibu EDM Consumable Parts Water Nozzle Lower 4465971