General Aluminum Die Gravity Casting Exhaust System Part

Overview Product Description Aluminium Die Cast Lighting Arm Adapter Adjustable Pole Parts Street Light Pole Mounting Br

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | OEM |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 5 |

| Casting Surface Quality Level | 2 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Surface Treatment | Sand Blasting, Polishing, Powder Coating,Anodizein |

| Applicaition | Auto Parts, Machinery Parts, etc... |

| Auto Parts | Ppap, Imds |

| Testing Report | Material Report, Dimension Report |

| Testing Way | CMM |

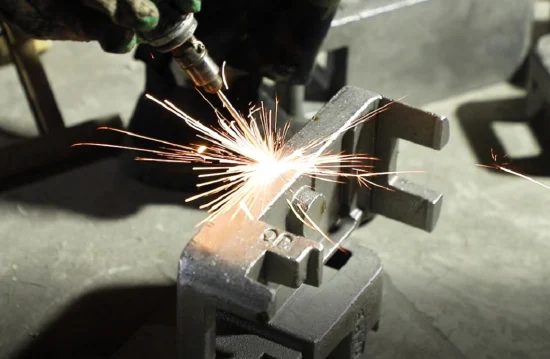

| Secondary Machining | Milling, Tapping, Grinding |

| Weight | 3G-100kg |

| Die Casting | Hot Die Casting and Cold Die Casting |

| Lead Time | 25-30days |

| Material Grade | ADC12,A380,B390 etc... |

| Transport Package | Carton Box+Pallet or Wooden Box |

| Specification | No-Standard |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 100ton Per Month |

Product Description

Product Description

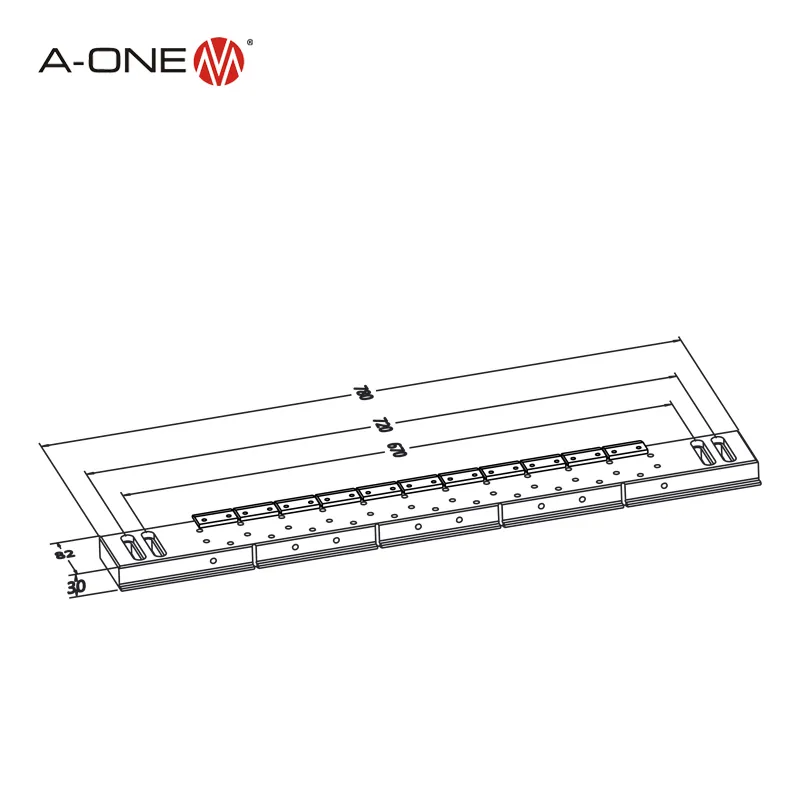

Aluminium Die Cast Lighting Arm Adapter Adjustable Pole Parts Street Light Pole Mounting Bracket for Street Light

1, Aluminium die casting is a process of injection aluminum alloy under pressure, which produces parts in high volume at low costs.2, There are two processes of Aluminum die casting: hot chamber and cold chamber.3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.4, Qingdao Xinghe Machinery Company Limited ---we have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.

5, Certification: TS16949, ISO9001, SGS, ROHSProduct Description

| Name | High Pressure Aluminum Zinc Die Casting Parts |

| Material | ADC12, A380, A356, ADC10, Zinc Alloy Zamak |

| Dimension | Mini 20*20 mm, Max800*800 mm |

| Technology | High Preressure Die Casting, CNC, CMM Measure, Painting, X-Ray Detection |

| Processing | 1, Sign Drawing (General clients provide the drawing or samples)2, Opening the Mold3, Die Casting ( Aluminium or Aluminium Alloy)4, Precision Machining (Burring, Lathe, Milling, etc)5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing6, Inspection and Packing |

| Application | Automobile 42%, Furniture 21%, Industry 18%, Lighting 15%, Other 4% |