Jtc Tool CNC Drilling Machining Center Drilling and Milling Machining High Processing Precision China High-Speed Drilling and Milling Machining Center

Overview DONGGUAN JTC TOOL CO., LTD.JTC TOOL CNC Drilling Machining Center Drilling And Milling Machining High Processin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | T600 |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Product Name | Drilling Tapping Center |

| Model | T600 |

| Keywords | Drilling Tapping Center |

| The X/Y/Z Axis Travel | 600/400/300 mm |

| Motor Power of X/Y/Z | 2.3/2.3/3.3 Kw |

| Movement Speed of X/Y/Z | 48/48/48 M/Min |

| Distance(Nose to Workbench) | 150-450 mm |

| Motor Power of Spindle | 4.1/10 Kw |

| Speed of Spindle | 20000 Rpm |

| Taper of Spindle | Bt30-100 |

| Transmission of Spindle | Direct Type |

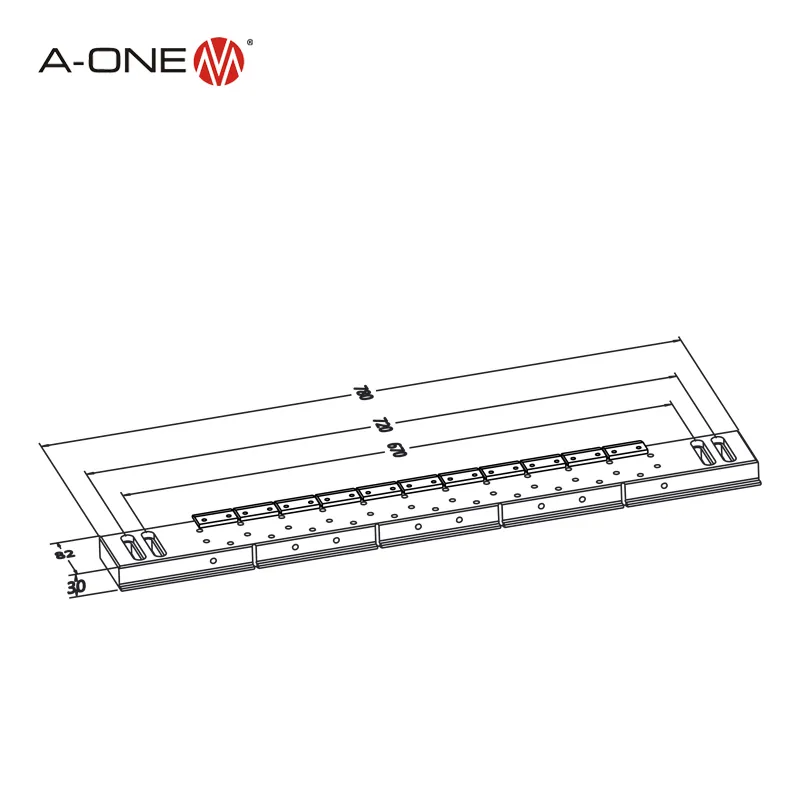

| Size of Workbench | 700*400 mm |

| Max.Capacity of Workbench | 250 Kg |

| T-Slot Size | 14t*3*125 |

| Max. Weight of Tool | 3 Kg |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | JTC TOOL |

| Origin | Guangdong, China |

| Production Capacity | 10000set/Month |

Product Description

DONGGUAN JTC TOOL CO., LTD.JTC TOOL CNC Drilling Machining Center Drilling And Milling Machining High Processing Precision China High-Speed Drilling And Milling Machining CenterProduct Description

Product Parameters

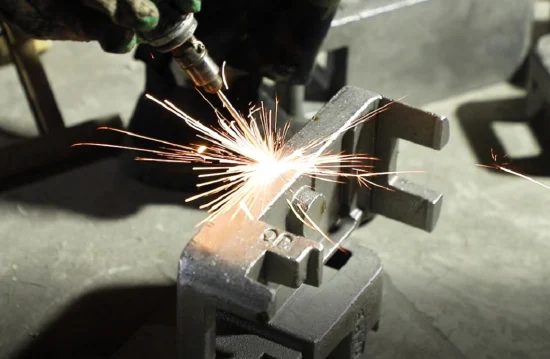

Detailed Photos