CNC Vertical Milling Machine Center Tc-855 with Fanuc Control

Overview Product Description 3 Axis 4 Axis 5 Axis Vertical CNC Milling Machine Center for Metal Heavy Cutting Tc-855 Vmc

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | TC-855 |

| Warranty | One Year Warranty |

| Application | Metal |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Open-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.003~0.005(mm) |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Machine Name | Vertical CNC Milling Machine |

| Controlling Mode | CNC System |

| X/Y/Z Axis Travel | 800/550/550mm |

| Cutting Feed Speed | 0-15000mm/Min |

| Worktable Size | 1000*550mm |

| Spindle Taper | Bt40 |

| Brand | Chansin |

| Transport Package | Plywood Case |

| Specification | 2750x2750x2850mm |

| Trademark | Trade Mark |

| Origin | Dongguan, Guangdong, China |

| HS Code | 8530800000 |

| Production Capacity | 50 Sets Per Month |

Product Description

Product Description

3 Axis 4 Axis 5 Axis Vertical CNC Milling Machine Center for Metal Heavy Cutting Tc-855 Vmc855

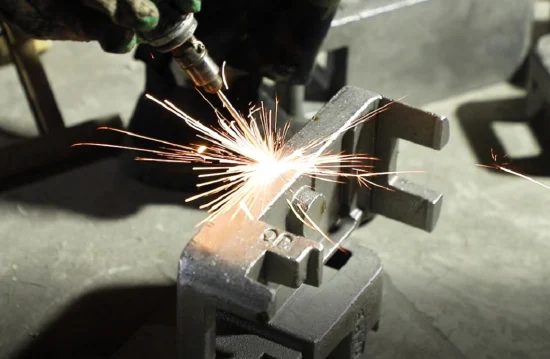

VMC855 is designed for machining complicated mold profile, automotive parts, and housing parts. It has distinguished advantage in machining mold, especially the small size mold. It has big torque output at low speed range, which is suitable for high strength steel and high temperature alloy steel which are difficult for machining.

Suitable to machine large machinery parts, automotive part, mold etc.With Taiwan high speed spindle to 10000rpm;High accuracy; High speed; High rigidity; Low noise .

Features At A Glance

VMC855 advantages:1: The spindle has good rigidity, and adopts a 1:1 belt with a high torque output of 11KW.

2: The slide block of the Y/Z axis guide rail is enlarged to maintain better cutting rigidity and carry a larger load during heavy cutting.

3: The entire machine tool castings are tempered and naturally aged to better eliminate internal pressure and achieve better stability.

Detailed Photos

Taiwan Brand Spindle 10000rpm Taiwan Brand Tool Magazine 24 tools Work Table 1000*550mm Taiwan TJR 4th Axis Rotary Table with Tailstock Taiwan TJR 4th and 5th Axis Rotary Table

Quality Control

Body parallelism and perpendicularity test:To insure the accuracy of the machine, we will do the parallelism and perpendicularity testing . All joint surface of the machine body are manually scraped to ensure geometric accuracy and rigidity.Reishaw laser interferometer inspection:

Detecting the screw pitch error and the straightness of the linear guide rail in the XX and YY directions. Meanwhile, test the actual positioning accuracy and repeat positioning accuracy of the machine.Running test:In order to ensure quality , the machine will go through other quality control procedures, such as spindle vibration , noise inspection, 72-hour full function running test.

Product Parameters

| TC-855 heavy-duty roller three-linear guides machining center parameters: | ||||

| 1 | Machine Body | Casting three linear guide ways high-strength body(X35mm, Y-axis 45mm, Z-axis 45mm six-slide linear roller rail) | ||

| 2 | Spindle | Taiwan WLT / TD / VOLIS 10000 rpm synchronous belt spindle | ||

| 3 | System | Taiwan Syntec/Japan Fanuc/Japan Mitsubishi/ Germany Siemens | ||

| 4 | Spindle Motor | The servo motor that comes with the system 11KW | ||

| 5 | Three-axis motor | The system comes with servo motors X, Y, Z-3KW | ||

| 6 | Automatic lubrication system | pressurized volumetric automatic oiler, automatic balance distribution of lubricants (joint venture Baoteng brand oiler) | ||

| 7 | Machine Head balance system | Servo screw direct drive | ||

| 8 | High pressure chip system | high pressure motor, high pressure flushing (joint venture Sinaer brand water pump) | ||

| 9 | Screw | original Taiwan imported Hiwin /PMI screw | ||

| 10 | Spindle cooling | plus independent oil cooling system (joint venture Ruike brand oil cooler) | ||

| 11 | Tool Magazine | Taiwan OKADA arm type with 24 BT40 tools capacity | ||

| 12 | Controller | Standard Syntec/Fanuc/Mitsubishi/Siemens color display | ||

| 13 | X, Y, Z bearings | standard German brand or Japan NSK | ||

| 14 | Three-axis roller guide | standard Taiwan Taiwan Hiwin / PMI | ||

| 15 | Spindle Knife cylinder | Standard Taiwan North Kui / Hao Cheng | ||

| 16 | Couplings | Standard Germany BK3 SW*J | ||

| 17 | Wind system combined with solenoid valve (triple) | standard joint venture Ogreut | ||

| 18 | The main electrical accessories | standard Germany Brand, Merlin Gerin | ||

| 19 | Other air pressure components | standard joint venture Ogreut | ||

| 20 | Circuit breakers, relays | standard Germany brand, Merlin Gerin | ||

| 21 | Electric box air fan | standard joint venture FuRuize | ||

| 22 | Transformer | standard joint venture AoHengda | ||

| 23 | Work LED lamp | standard Taiwan Ou Si | ||

| 24 | Hand control electronic hand wheel | standard Taiwan NEMICON | ||

| 25 | Three-axis telescopic shield | standard joint venture Zhenfei | ||

| 26 | Full cover | standard joint venture Jiancheng/Hongwang | ||

| 27 | Technical advantages | 1. High-speed and stable large body2. Superb and advanced shovel assembly technology3. Precise and advanced laser detector adjustment accuracy4. Strict and demanding seismic test5. High-quality elite technical team6. Perfect Quality control and after-sales service system | ||

| Content | Unit | Parameters | Remarks | |

| X/Y/Z-Axis Travel | mm | 800/550/550mm | ||

| Distance from Spindle Nose to Table | mm | 120-720mm | ||

| Distance from Spindle Center to Column Guide Rail | mm | 590mm | ||

| Working Table Size | mm | 1000×550mm | ||

| Table Max Load | kg | 800kg | ||

| T Slot | mm | 5pcs×18T×90mm | ||

| Spindle Speed | r/pm | 10000rpm | ||

| Spindle Motor Power | kw | 11kw | ||

| X/Y/Z-Axis Motor Power | kw | 3.0/3.0/3.0kw | ||

| X, Y, Z three axis | mm | X axis -35mm, Y axis -45mm, Z axis -45mm roller linear guide | Z axis -six slider | |

| Rapid Traverse(X/Y/Z) | mm/min | 36000/36000/36000mm | ||

| Cutting Speed | mm/min | 0-15000mm | ||

| Spindle Taper Diameter | / | BT40 | ||

| Positioning Accuracy | mm | ±0.005mm/300mm | ||

| Repeat Positioning Accuracy | mm | ±0.003mm/300mm | ||

| Total Electricity Demand | KVA | 19kw | ||

| Machine Size | mm | 2750×2750×2850mm | ||

| Machine Weight | T | 5.5T | ||

| Accessories | 1.Tool box (1 set)2.Tool Holder(2 pcs)3.6 inch vise (1pcs)and Lock knife seat (1 set)4.Machine operating manual5.Operation and programming manual6.Servo Motor and Controller Manual | |||

Company Profile

FAQ

Q1: How can I choose the most suitable machines ?A1: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

Q2: What's your main products of your company?

A2: We specialized in CNC Milling Machine ,Vertical Machining Center ,Lathe Machines , Drilling Machine, Tapping Machine and so

on.

Q3: What's the Payment Terms ?

A3: T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight.

Q4: What's the MOQ?

A4: 1set

Q5: What's the warranty?

A5: One year.

Related Products

-

![EDM Filter Agie Charmilles Fanuc Sodick Dhf-25A]()

EDM Filter Agie Charmilles Fanuc Sodick Dhf-25A

-

![Ds-40, Tw-40 Mitsubishi, Seibu, Hitachi, Makino, Chmer, Accutex 300*59*500 Wire Cut EDM Filter]()

Ds-40, Tw-40 Mitsubishi, Seibu, Hitachi, Makino, Chmer, Accutex 300*59*500 Wire Cut EDM Filter

-

![Accutex Carbide Power Feed Contact Upper and Lower According to Accutex Pw020001]()

Accutex Carbide Power Feed Contact Upper and Lower According to Accutex Pw020001

-

![Vehicle Engine Part 4D30 Piston Ring for Mitsubishi Competitive Price and High Quality Customized Standard]()

Vehicle Engine Part 4D30 Piston Ring for Mitsubishi Competitive Price and High Quality Customized Standard