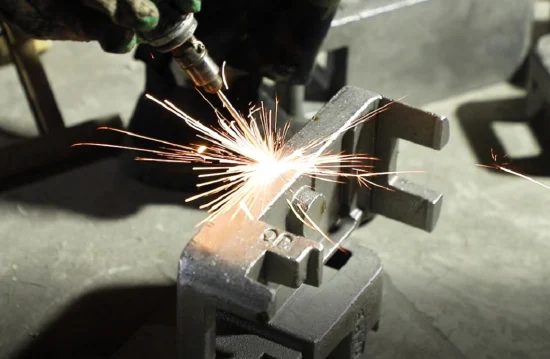

a-One Sodick EDM Steel Electrode Holder 3A-520115

a-One Sodick EDM Steel Electrode Holder 3A-520115 Detailed descriptions Our products advantages1. 3A fast positioning fi

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 3A-520115 |

| After-sales Service | Online Support |

| Warranty | 3 Months |

| Logo Printing | Available |

| Size | Small |

| Customized | Non-Customized |

| Type | Steel Holder |

| Material | Stainless Steel |

| Certification | ISO 9001:2008, ISO 9001:2000, CE |

| Version | Each Contains 4 Fixed Screws |

| Application | for Holding Oblong Electrode or Workpiece |

| Hardness | HRC30-36 |

| MOQ | 12 PCS |

| Nw | 0.595kg |

| Package | Carton |

| Accuracy | 0.002mm |

| Condition | 100% New |

| OEM Service | Available |

| Transport Package | Inner Packed with Black EPE, and with Paper Box |

| Specification | 3A-520115 |

| Trademark | A-ONE |

| Origin | Shenzhen, China |

| HS Code | 8466200000 |

| Production Capacity | 50000 PCS/Year |

Product Description

a-One Sodick EDM Steel Electrode Holder 3A-520115Detailed descriptions

| Material | S136 |

| Hardness | HRC30-36 |

| Version | Each contains 4 fixed screws,set of 12 units |

| Application | For holding the largest 30mm oblong electrode or workpiece |

| Fast | Clamping in seconds,the way of clamp traditional manual lock clamp , greatly reduce manual work and save time |

| Save | Save aligment of processing, suitable for variety and special workpiece processing, achieve free preset and detection on outside |

| Precision | Unique standard interface, precise repeatability |

Shenzhen Jingzuan Intelligent Manufacturing was established in 2000 and specialized in designing, manufacturing and sales of 3A fast positioning JIG system, zero point system, ball lock shaft system and all kinds of un-standard JIG, CNC machine collet chuck, guide sleeve, and ect machine tool accesssories. Shenzhen company covers an area of 3,000 square meters. The company has the advanced production facility introduced from Germany, Switzerland, the USA and Japan, such as JUNG form grinding machine and ELB high-precision surface grinding machine of Germany, MOORE jig grinding machine of USA, internal and external grinding machine and thread grinding machine of Switzerland, and OKUMA machining center and TSUGAMI numerical control machine of Japan. The company established constant-temperature grinding room of 20±0.5°C and high-precision constant temperature measuring center, and introduced high-precision measuring equipment, such as German ZEISS coordinate measuring machine, ZEISS tool microscope and TESA MIVRO-HITE altimeter.The stable quality and high cost performance ratio are highly appreciated by domestic and overseas customers.Our company fully implemented ISO 9001 quality management system and is a great asset to high quality products of the company.

| How to Order? |

| Step 1 please tell us what model and quantity you need; |

| Step 2 then we will make a PI for you to confirm the order detail; |

| Step 3 when we confirmed everything, arrange the payment; |

| Step 4 finally we deliver the goods within the stipulated time. |

| DeliveryTime |

| Small Order:in stock normally,deilver goods once payment received |

| Large Order: 5-7 days |

| OEM Order: 7-15days |

| OEM logo Service |

| we supply service of marked logo and wipe off logo, please note wipe off logo is a little expensive |

| After-sales Service |

| 1. chucks warranty:1 year |

| 2. If you find any defective accessories in the first order, we will give you thenew parts for free to replace in the next order, the fact is that our productsfraction defective rate is lower than 1%. |

Welcome to choose A-ONE company as your long-term relationship supplier!

Related Products

-

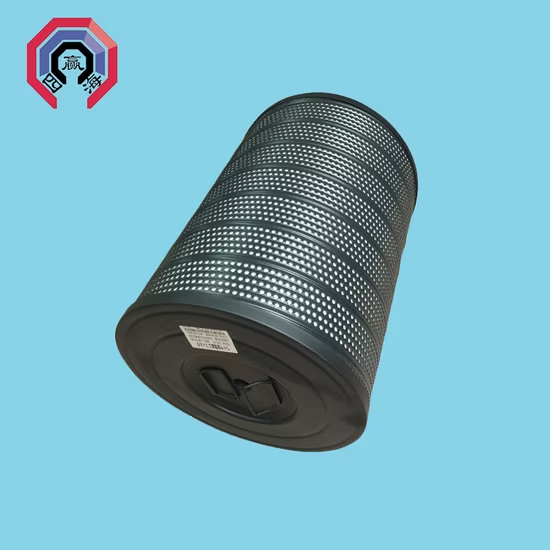

![Zl-32 Agie Charmilles Wedm Consumables 340X25X450mm Wire EDM Filter H342240 135007724 951100041]()

Zl-32 Agie Charmilles Wedm Consumables 340X25X450mm Wire EDM Filter H342240 135007724 951100041

-

![Agie Charmilles Wire EDM Wear Parts Geared Belt 1768-Mxl-050, 449.07*2.032*12.7mm]()

Agie Charmilles Wire EDM Wear Parts Geared Belt 1768-Mxl-050, 449.07*2.032*12.7mm

-

![a-One Sodick EDM Steel Electrode Holder 3A-520115]()

a-One Sodick EDM Steel Electrode Holder 3A-520115

-

![JLM-508 Machinery Horizontal Turning Machine Tool Z-Axis 500mm Mitsubishi Control System CNC Lathe]()

JLM-508 Machinery Horizontal Turning Machine Tool Z-Axis 500mm Mitsubishi Control System CNC Lathe