Super Good Quality Optimized High Speed Parts 1160 Processing Machining Center

Overview Specification Main parts list: Optional configuration: - SIEMENS/FANUC/Mitsubishi CNC Controller - 4th/5th axes

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | BF-V11 |

| After-sales Service | Provide |

| Warranty | 1 Year |

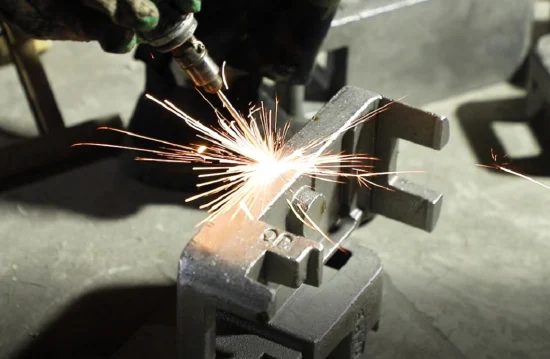

| Application | Metal |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Controller System | Mitsubishi M80 /Fanuc 0I-Mf/Siemens 828d |

| Rapid Feed | 36m/Min |

| Spindle Speed | 12000/15000/18000rpm or Higher |

| Transport Package | Wooden Package |

| Specification | 3200*2900*3000mm |

| Trademark | BAOFENG |

| Origin | China |

| HS Code | 84571010 |

| Production Capacity | 4000 |

Product Description

Specification| TRAVEL | |

| X/Y/Z axis travel | 1100x600x600mm |

| Spindle nose to table | 100-700mm |

| Spindle center to column | 690mm |

| Positioning accuracy | ±0.003/300mm |

| Repeated positioning | ±0.002/300mm |

| Spindle | |

| Spindle taper | BT40 |

| Spindle transmission | Direct drive |

| Spindle speed | 12000 rpm/min |

| Controller | |

| CNC control | Fanuc 0i-MF |

| Spindle motor | 11/15 kw 12000 rpm/min |

| X/Y/Z motor | 3.0/3.0/3.0kw |

| Table | |

| Table size ( W x L ) | 1200x600mm |

| T slot | 5-18x100mm |

| Table load | 800kg |

| Feed | |

| X/Y/Z rapid feed rate | 36/36/36m/min |

| X/Y/Z linear guideway | Roller type 45/45/45 |

| X/Y/Z ball screw | 12mm-ball |

| MACHINE DIMENSION | |

| Dimension | 3200X2900X3000mm |

| Weight | 6500kg |

Main parts list:

| Item | Brand |

| Spindle | Taiwan-Spintrue |

| Spindle bearing | Japan-NSK |

| Ball screw | Taiwan-PMI-C3 |

| Linear guideway | Taiwan-PMI |

| Pneumatic parts | Taiwan-Mindman |

| Electric parts | Japan-Mitsubishi/Omron |

| Tool magazine | Taiwan- 24T Arm type |

Optional configuration:

- SIEMENS/FANUC/Mitsubishi CNC Controller

- 4th/5th axes rotary table

- Chip conveyor

- Tool setter

- Oil mist collectorDescription

- 3 axes adopt ball guideway, rapid feed speed 36 meters/min.

- Special large span structure of the machine base and column is able to bear high inertia gravity and improve the dynamic responsiveness of the whole machine.

- Shortnose design of direct connection high-speed spindle with excellent rigidity, increase efficiency and reduces abrasion of the tools. Maximizes the transmission efficiency of the spindle motor and also increases processing accuracy and spindle durability.

- The machine employed backward chip removal with mass flow chip flushing system suits particular parts processing for faster chip removing.

Parts

Baofeng Machine

Common Machines

Casting

HT300

HT200/250

Screw

X/Y/Z axis screw pretension

/

Design Concept

Golden ratio

/

Spindle Vibration Standard

V1

V4

Oil-water Separation Design

At the rail

/

Contact Surface Scraping

Manual scraping

Gasket/Grinding Machine

Rail Surface Installation

Milling and grinding processing

Only milling processing

Sheet Metal Cover

2.0 / 2.5mm

1.8mm

FAQ

1. How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model.You can also send us the products drawing, we will choose the most suitable machines for you.2. What are your trade terms?

A: FOB, CFR, and CIF are all acceptable.3: What are the Payment Terms?

A: Usually 30% deposit T/T in advance, 70% balance payment before shipment; Irrevocable LC at sight. Special circumstances can be negotiated.4. What's the MOQ?

A: please negotiate with us.If you need a machine with your own specification, logo, packing, etc,

Related Products

-

![Grade a of Copper Wire/Copper Granules/Copper Wire Scrap Used on Agie-Charmilles, Sodick, Mitsubishi and Makino]()

Grade a of Copper Wire/Copper Granules/Copper Wire Scrap Used on Agie-Charmilles, Sodick, Mitsubishi and Makino

-

![Makino EDM Spare Parts Ma002 Current Supply, Upper & Lower Power Feed Contact 19L*4t*10W mm, Z248W0100100]()

Makino EDM Spare Parts Ma002 Current Supply, Upper & Lower Power Feed Contact 19L*4t*10W mm, Z248W0100100

-

![Agie Wire Guide 0.20mm 333.016.574, 333016574]()

Agie Wire Guide 0.20mm 333.016.574, 333016574

-

![GDST OEM MB122011 Auto Steering Parts Tie Rod Ends for Mitsubishi]()

GDST OEM MB122011 Auto Steering Parts Tie Rod Ends for Mitsubishi